If you’re reading this through a pair of glasses, there’s a better-than-zero chance your lenses were manufactured by Essilor. But there’s an equally good chance you’ve never heard of Essilor, much less noticed the French company’s U.S. headquarters along Interstate 35.

“We are not a well-known company, but there are something like one billion people using our products every day,” says Eric Leonard, president of Essilor of America.

Among those products are photochromic lenses that darken in sunlight (Transitions is an Essilor brand) and progressive lenses that provide corrective vision at multiple distances without the lines associated with bifocals (Varilux). The company is also an industry leader in the use of polycarbonate materials that resist impact, and it produces a variety of coatings that reduce scratches, smudges, and/or glare (Crizal).

Essilor’s roots go back to 1849 in France. Today, the company has about 60,000 employees globally, including 10,000 in the United States, about 1,200 of whom are in the Dallas-Fort Worth area. Most of those are based at Essilor’s 26-acre campus fronting I-35 in Farmers Branch; it includes the Omega Lab — which operates around the clock, producing nearly 6,000 pairs of lenses per day — as well as the firm’s Center of Innovation & Technology.

For the past few years, the company’s innovative focus has been on trying to minimize eye exposure to dangerous light, including ultraviolet light and high-energy blue-violet light. Both types come from the sun, but the latter type is also generated indoors by fluorescent bulbs and flat-screen televisions.

“The eye is a very fragile part of the body, and it’s important to move out the high-energy light,” Leonard says.

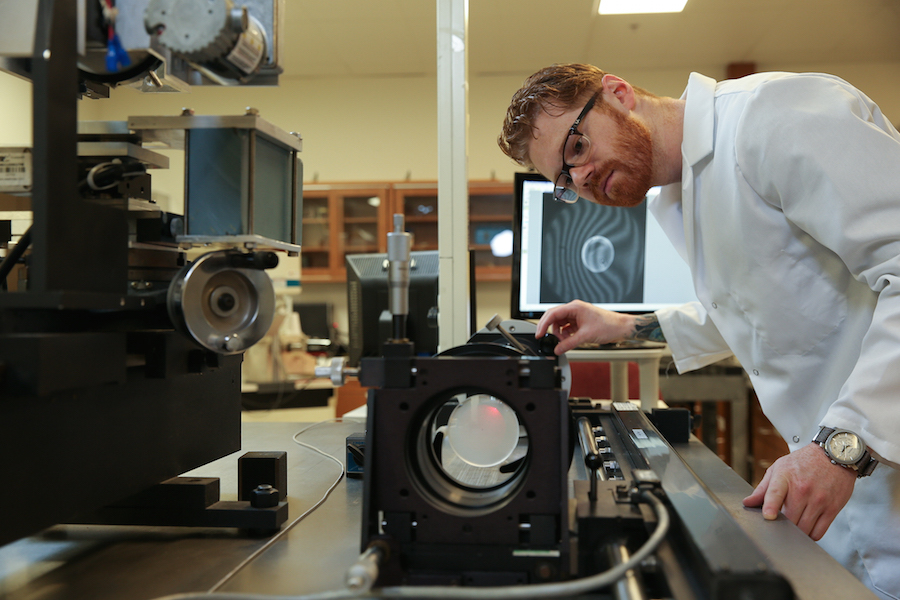

At the Center of Innovation & Technology, Essilor’s Research and Development and Global Engineering departments work side by side. The hallways are lined with plaques commemorating dozens of patents; two of the ones awarded last fall were for a “method for preparing a thermoplastic polyurethane of improved yellowness index, and optical articles made therefrom” and for “curable coating compositions providing antistatic abrasion-resistant coated articles.”

Phil Miller, Essilor’s vice president for North American research and development, has been named as an inventor on more than 10 U.S. patents. He encourages his employees to devote 15 percent of their time to exploratory work; they can also apply for a Vision Forward Grant to receive funding and/or resources to develop new ideas.

“What I try to do is give people the opportunity to innovate,” Miller says.

When he was recruited by Essilor, Miller’s initial reaction was to joke about how innovation in the eyeglasses field pretty much ended with Benjamin Franklin. Of course, Franklin and the rest of the Founding Fathers never could have envisioned a time in which most Americans spend a large portion of their waking hours staring at light-generating devices.

“What’s fascinating about our industry is the needs of the people are changing constantly,” Leonard says.

For a daily dose of what’s new, now, and next in Dallas-Fort Worth innovation, subscribe to our Dallas Innovates e-newsletter.